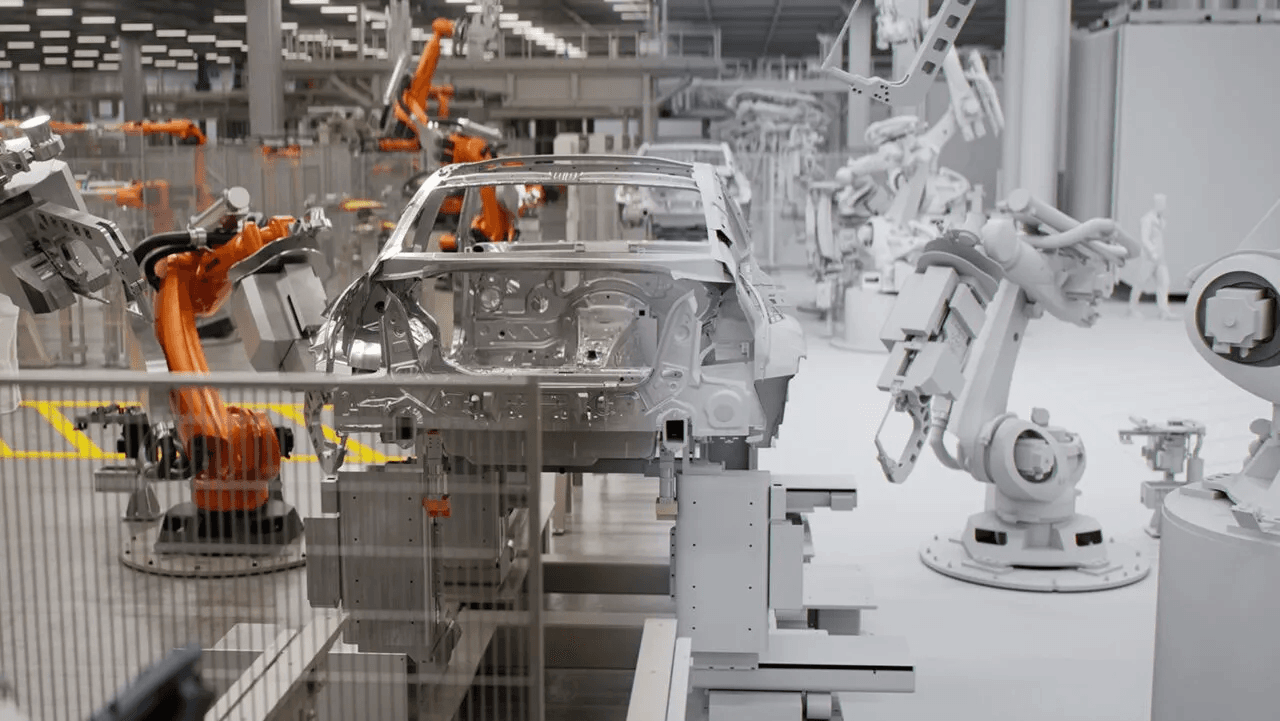

BMW is leveraging NVIDIA's Omniverse platform to revolutionize its manufacturing process. The collaboration focuses on building Digital Twins in BMW's global production network, which optimizes the layout, robotics, and logistics systems of the plant.

- <strong>Virtual Factory Plan</strong>: With Omniverse, BMW can design virtual plants, which can help them simulate and solve problems in real factories in advance, helping to increase factory efficiency and reduce costs.

- <strong>Real-time Collaboration</strong>: Omniverse enables a diverse team at BMW to collaborate in real-time, enabling global teams to work in the same virtual environment and make fast and accurate decisions.

- <strong>Robot and logistics optimization</strong>: BMW leverages Omniverse to optimize the robot's deployment and logistics system. This helps robots operate efficiently within the plant, and contributes to reducing production time.

- BMW's digital transformation: BMW is accelerating its digital transformation with Omniverse, which is instrumental in increasing efficiency and improving sustainability in its manufacturing process. - Working with NVIDIA: "Working with BMW will contribute to broadening the boundaries of virtual integration and virtual tooling for next-generation smart connected plants," NVIDIA CEO Jensen Huang noted.

BMW's collaboration with NVIDIA will bring about innovative changes in the manufacturing industry. It will play an important role in increasing the efficiency of the plant, reducing costs, and supporting sustainable growth. BMW plans to build a virtual plant using Omniverse at its electric vehicle plant in Debrecen, Hungary, in 2025, which will optimize production. Source: https://resources.nvidia.com/en-us-mfg-briefcase/bmw-group-nvidia-omn?lx=q8vaLh

Share this post: