See how Digital Twin technology integrates into various industrial fields to solve problems and create new value, through innovative templates and real-world application cases.

BMW is leveraging NVIDIA's Omniverse platform to revolutionize its manufacturing process. The collaboration focuses on building Digital Twins in BMW's global production network, which optimizes the layout, robotics, and logistics systems of the plant. Using Digital Twin - Virtual Factory Plan: With Omniverse, BMW can design virtual plants, which can help them simulate and solve problems in real factories in advance, helping to increase factory efficiency and reduce costs. - Real-time Collaboration: Omniverse enables a diverse team at BMW to collaborate in real-time, enabling global teams to work in the same virtual environment and make fast and accurate decisions. - Robot and logistics optimization: BMW leverages Omniverse to optimize the robot's deployment and logistics system. This helps robots operate efficiently within the plant, and contributes to reducing production time. Meaning of cooperation - BMW's digital transformation: BMW is accelerating its digital transformation with Omniverse, which is instrumental in increasing efficiency and improving sustainability in its manufacturing process. - Working with NVIDIA: "Working with BMW will contribute to broadening the boundaries of virtual integration and virtual tooling for next-generation smart connected plants," NVIDIA CEO Jensen Huang noted. Future outlook BMW's collaboration with NVIDIA will bring about innovative changes in the manufacturing industry. It will play an important role in increasing the efficiency of the plant, reducing costs, and supporting sustainable growth. BMW plans to build a virtual plant using Omniverse at its electric vehicle plant in Debrecen, Hungary, in 2025, which will optimize production. Source: https://resources.nvidia.com/en-us-mfg-briefcase/bmw-group-nvidia-omn?lx=q8vaLh

Mar 27, 2025

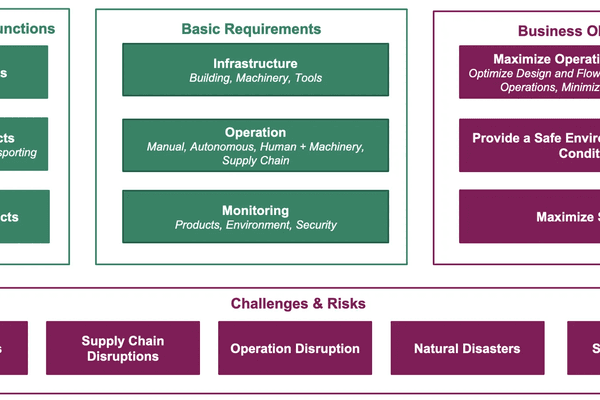

NVIDIA's Omniverse platform is instrumental in leveraging Digital Twin technology in the logistics and manufacturing industries to increase operational efficiency and reduce costs. Digital Twin is a virtual replica of a real physical system, allowing you to simulate and optimize different scenarios. Using Digital Twin - Distribution Center Optimization: Large distribution centers like Amazon leverage Omniverse to build digital twins of distribution centers, which help optimize design and flow2[3] (https://docs.omniverse.nvidia.com/digital-twins/latest/warehouse-digital-twins/use-cases.html) . - Manufacturing process optimization: Samsung builds digital twins of semiconductor manufacturing plants through Omniverse, which improves process efficiency and yields1. The benefits of digital twins - Simulation and testing: Digital twins can simulate and test a variety of scenarios in a safer and more cost-effective way than testing in real-world settings. This helps reduce the risks posed by the introduction of new technologies in the logistics and manufacturing industries [4] (https://www.plainconcepts.com/warehouse-digital-twin/) [6] (https://www.codasol.com/digital-twins-warehouse-management/) ). - Predictive maintenance: Digital twins are connected to IoT sensors to monitor the condition of equipment in real time, and contribute to reducing emergency 停 pages through predictive maintenance [5] (https://docs.omniverse.nvidia.com/digital-twins/latest/building-warehouse-digital-twins.html) [8] (https://addverb.com/digital-twin-in-warehouses-benefits-and-applications/) ). - Space optimization: Digital twins help optimize space in distribution centers to maximize storage capacity and increase work efficiency [9] (https://kotrak.com/en/blog/digital-twin-in-logistics-and-warehousing/) . Future outlook Digital twin technology will bring about innovative changes in the logistics and manufacturing industries. It will play an important role in increasing operational efficiency, reducing costs, and improving customer satisfaction. Technologies such as NVIDIA's Omniverse platform will accelerate this innovation and contribute to increasing the utilization of digital twins in more industries. Source: https://docs.omniverse.nvidia.com/digital-twins/latest/warehouse-digital-twins/use-cases.html

Mar 27, 2025

NVIDIA's Isaac platform leverages the latest Generative AI and advanced simulation technology to accelerate AI-driven robotics. The platform is instrumental in increasing robot efficiency and improving task accuracy in manufacturing and logistics industries. Key features of Isaac - Isaac Manipulator: Provides state-of-the-art motion generation and modular AI capabilities for robotic arms. It enables robots to recognize and interact with their surroundings and can combine software components customized for different tasks2[3] (https://blogs.nvidia.co.kr/blog/isaac-generative-ai-manufacturing-logistics/) . - Isaac Perceptor: Provides visual AI to autonomous mobile robots (AMRs), increasing efficiency in logistics and manufacturing operations with multi-cameras and 360-degree vision capabilities. It is being leveraged by companies such as ArkBest, BYD and Keon Group2[3](https://blogs.nvidia.co.kr/blog/isaac-generative-ai-manufacturing-logistics/). - Isaac Sim: A simulation tool based on NVIDIA Omniverse, used to simulate and validate robots in physically accurate environments. This accelerates training of AI models through the generation of synthetic data [6] (https://seo.goover.ai/report/202407/go-public-report-en-bace6a03-0bcc-438d-a356-d3d30d7b4ea2-0-0.html) [8] (https://nvidianews.nvidia.com/news/robotics-industry-development-ai-autonomous-machines) ). Industrial application - Manufacturing: NVIDIA Isaac enables robots to detect, adapt and reprogram in a variety of tasks, including smart manufacturing, pick-and-place work, machine manipulation and assembly. It is being offered to customers by companies such as Yasukawa, Solomon, Picnic Robotics and more2[3](https://blogs.nvidia.co.kr/blog/isaac-generative-ai-manufacturing-logistics/). - Logistics: The Isaac AMR platform creates a digital twin of the distribution center to support path optimization and simulation of autonomous mobile robots, which contributes to increasing logistics efficiency and improving worker safety [5] (https://www.roboticstomorrow.com/story/2022/01/nvidia-builds-isaac-amr-platform-to-aid-10-trillion-logistics-industry/18013/) [7] (https://www.smartindustry.com/tools-of-transformation/robotics/news/11288999/product-news-nvidias-isaac-amr-platform-for-the-logistics-industry) ). Future outlook NVIDIA Isaac is accelerating the development of AI-based robotics in the manufacturing and logistics industries. This will play an important role in increasing the efficiency of robots and improving the accuracy of tasks. NVIDIA's technology is expected to bring about innovative changes in various industries. Source: https://blogs.nvidia.co.kr/blog/isaac-generative-ai-manufacturing-logistics/

Mar 27, 2025

Samsung recently leveraged NVIDIA's Omniverse platform to build a digital twin of the semiconductor manufacturing process, which is focused on increasing production efficiency and improving yield. The platform creates a digital replica of a semiconductor manufacturing plant, enabling simulation and optimization to be performed in the same environment as the actual plant. Vision of Digital Twin Samsung aims to make it easier for business users to develop and utilize their use cases through digital twin platforms. It focuses on fast processing large-scale data and supporting different business cases, including optimization of HyperScale and LoadTime13. The journey of the digital twin Samsung started Proof of Concept (PoC) in collaboration with NVIDIA in 2022. In this process, we used Omniverse to set up the first Fab digital twin model and validate 3D modeling capabilities based on real Fab data13. - 3D Data Consolidation: Samsung has experienced many challenges in integrating large-scale 3D data and processing data in different formats. However, it has worked with NVIDIA to address these issues and successfully built Fab's digital twin13. - Model loading times: Samsung aims to reduce loading times for its digital twin models to less than 5 minutes, which is critical to analyzing and optimizing data in real time13. Future outlook Samsung Electronics aims to build a fully automated Fab by 2030. The digital twin platform is expected to play an important role in achieving these goals. This will increase the efficiency of the semiconductor manufacturing process and contribute to improving the yield 13. The importance of cooperation Through its collaboration with NVIDIA, Samsung was able to successfully introduce the Omniverse platform. The initial collaboration with NVIDIA was essential to the success of the Digital Twin project, which will bring about an innovative change in the semiconductor industry. Source: https://resources.nvidia.com/en-us-industrial-sector-resources/gtc24-s62610

Mar 27, 2025