Operation-V

POLLUX's OPERATION-V is a distributed processing AI engine for omni-channel logistics. It automates and optimizes complex logistics operations in real-time, improving inventory accuracy, enhancing work productivity, and reducing operational costs. Implemented with MSA and cloud-native architecture, this solution provides integrated management of orders across diverse channels.

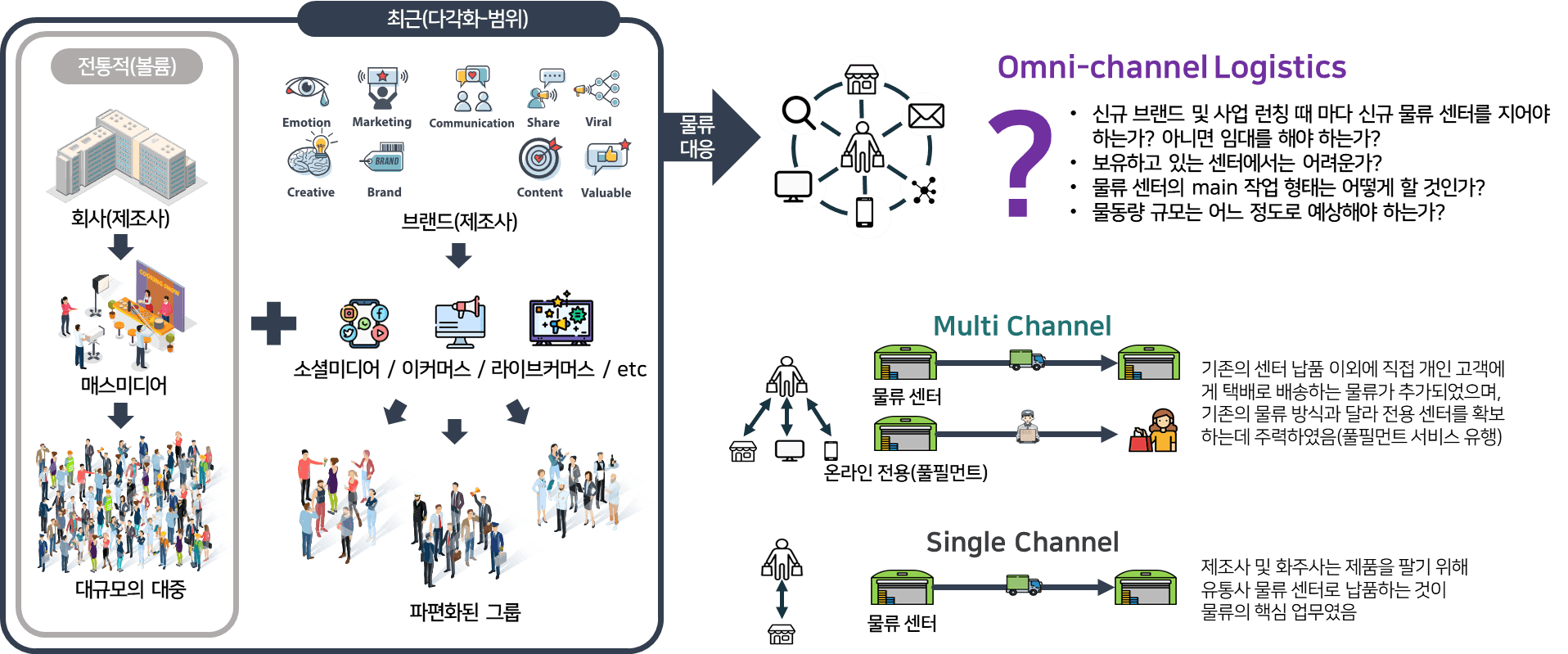

Logistics Industry Status and Service Challenges

Today's logistics centers face a surge in both online and offline orders, with complex processing of orders, shipments, and receipts across multiple sales channels. Managing inventory quantities for various shippers and specialized inventory information requires detailed management. When logistics operations and detailed information are poorly managed, inventory accuracy and visibility decline, leading to unnecessary work, inventory waste, missed shipments, increased costs, and deteriorating customer service.

Omni-Chain Logistics Solution: Operation V

To establish an integrated and shared logistics system and solve many problems, the focus should be on efficiently managing detailed logistics center operations rather than macro logistics operations. From order to outbound/inbound operations, planning must be detailed to increase control over overall logistics operations and inventory, enabling task integration and flexible infrastructure operation as needed. This solution (Oper-V) automates and optimizes all logistics center business processes in real-time, from order processing to inventory and work planning/execution. This enables Omni-Channel logistics and allows integrated operation of logistics for multiple shippers. For this purpose, Oper-V is implemented based on MSA (Microservices Architecture) and cloud-native, providing high computational performance, uninterrupted operation, and elastic scalability.

※ Omnichannel logistics is about converting diverse logistics service requirements arising from omnichannel marketing into logistics standards, grouping and integrating them to reduce complexity and improve work productivity.

- Order Management: Collect and process orders from multiple channels (offline, online, platforms, etc.) in one place

- Inventory Management: Sequentially track all events affecting inventory, including receiving, inventory movement, inspection, shipping, and adjustments

- Work Planning and Execution: Automatically schedule work, assign batches, and coordinate picking, packing, and shipping operations based on order and inventory information

This entire process is automated, and through real-time processing, it flexibly responds to exceptional situations. Going beyond the simple inventory management and ordering functions provided by traditional ERP or WMS, it serves as an integrated platform that easily controls the 'entire logistics operation process'.

Oper-V's Differentiated Logistics Center Optimization and Automation

Operation-V Feature Introduction Video

- Real-time Work Planning and Execution

This solution's greatest strength can be summarized with the keyword 'real-time'.

- Work Distribution and Batch Allocation: The system automatically assigns work by analyzing which workers are needed in which areas and how much inventory remains in each zone.

- Real-time Exception Handling and Re-planning: When exceptions occur, the system responds immediately with automatic scheduling and inventory adjustment.

- Inventory Correction and Sequence Management: All moments of order entry, inventory movement, inspection, or physical counts are meticulously recorded with immediate inventory updates. If omissions or errors occur, the system identifies them and automatically creates inventory correction tasks.

This automation of scheduling, planning, and inventory correction allows operational staff to focus on more important decision-making and customer management. Since the system automatically handles all order processing, batch allocation, and work planning, it fully automates operational tasks that cannot be resolved by automated equipment alone.

- Sophisticated Inventory Management: 'Order Locking'

The Order Locking feature quickly identifies 'actually available inventory' from the logistics center's stock and allocates it to orders.

- Accurate inventory quantities are essential for allocating remaining stock to orders, requiring tracking of numerous simultaneous events (receiving, returns, exchanges, physical counts, other order allocations).

- This solution uses advanced sequence management technology to prevent duplicate allocations of the same inventory or shipping errors due to inventory shortages.

This real-time accurate reflection of 'available inventory' ensures smooth delivery to end customers and minimizes missed shipments and inventory shortages.

- Work Optimization through Order Sets

The Order Set feature automatically analyzes order patterns and configures the optimal work method for each order.

Work Optimization through Order Sets Explanation Video

For example, when there are many small multi-item orders, it might choose 'multi-picking followed by consolidated packaging,' or when there's a surge in large single-item orders, it might separate work into 'single-item dedicated lines.' The core purpose of Order Sets is to pre-configure workflows to prevent inefficiencies in picking and packing processes.

- This enables accurate and fast picking, packing, and shipping processes, allowing batch processing of orders from multiple shippers.

- High-Performance Computing Based on MSA and Cloud-Native Architecture

Logistics centers generate hundreds of thousands or millions of inventory, order, and work data points daily.

- To process this quickly, services are split using MSA (Microservices Architecture) for distributed parallel processing.

- Inter-service communication is entirely API-based, including internal module connections, making it easy to access needed functions and flexibly integrate with other solutions.

- Cloud-native architecture enables non-stop patching and automatic scaling, ensuring stable response even during peak traffic events or sale seasons.

- Expandability with AI Booster

AI technology is gaining significant attention in the logistics field recently.

- This solution actively utilizes API and Agent structures, making it easy to integrate with various AI models including reinforcement learning, optimization models, and LLMs.

- The vast amount of data generated in logistics center operations is absolutely advantageous for AI model training and improvement.

- This enables AI integration for work path optimization, packaging optimization, and even natural language report generation such as weekly exception reporting.

Oper-V Application Cases

- Productivity Improvements of 20-100% or More

- Current customers report that shipper integration has improved overall center productivity by an average of over 20%.

- During peak seasons like events or sales, some cases have achieved over 100% increase in processing volume compared to the previous year.

- Improved Inventory Accuracy → Sharp Decrease in Disposal and Missed Shipment Rates

- With real-time inventory management and order locking,

- Inventory disposal rates decreased by approximately 23%

- Missed shipment rates reduced by more than 20%.

For online orders, missed shipment rates decreased by nearly 50%, playing a significant role in 'online logistics stabilization'.

- Work Automation Reduces Labor Costs and Error Risks

- Automated work distribution, inventory correction, and scheduling systems allow staff to focus on high-value tasks such as exception monitoring, customer response, and strategy development.

- Simultaneously, errors such as inventory mix-ups and incorrect order allocations between workers have greatly decreased, improving overall logistics center operational stability.

Ready for AI

- LLM-Based Exception Reporting and Missed Shipment Management Agent R&D

- Among AI technologies, we are researching agents based on LLMs (Large Language Models) that automatically summarize and report weekly exceptions, and agents that track causes and suggest solutions when missed shipments occur.

- This allows managers to make quick decisions based on essential information provided verbally by the system, without having to search through complex reports or logs.

- Integration with Work Path and Packaging Optimization Models

- When logistics center movement paths are long or complex, travel time and labor costs increase, reducing efficiency.

- We plan to optimize work paths, routing, and packaging processes using reinforcement learning or optimization algorithms, and have already secured positive results through pilot applications with some customers.

- Continuous Expansion and Open API Enhancement

- The adoption of AI and smart devices (e.g., automated warehouse robots, AGVs) is accelerating throughout logistics services.

- Our solution will strengthen integration with various external equipment, platforms, and AI solutions through open API expansion.

- This will be a key driver in realizing larger-scale omni-channel logistics.